Search

-

Corrosion Resistant and non Magnetic Steel

- Ferritic and martensitic steels, incl. precipitaion hardening steel

- Austenitic steels

- Duplex and super duplex stainless steels

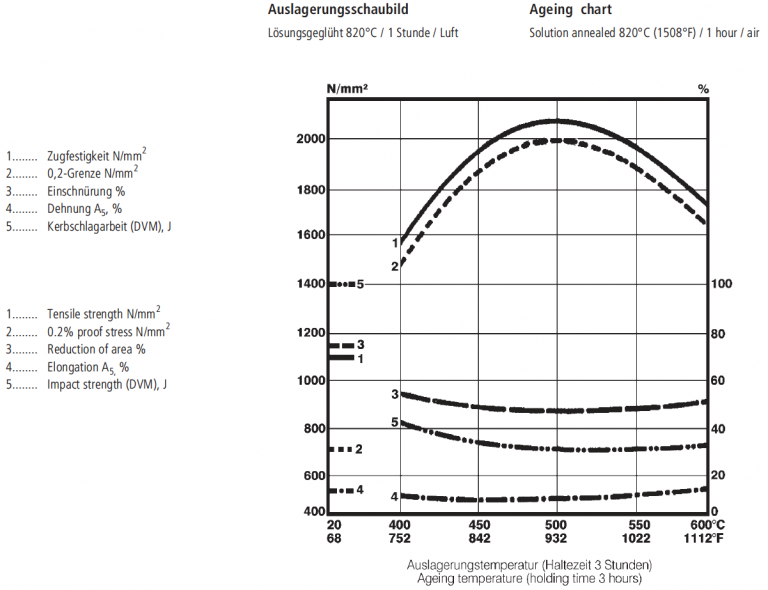

BÖHLER W720 VMR is not a classic hot work tool steel, but an ultra-high strength maraging steel. Compared to quenched and tempered steels, the material generates its high strength not through a hardened and tempered martensitic structure with a high carbon content and secondary hardening carbides, but through the precipitation of intermetallic phases from a tough nickel martensitic matrix. BÖHLER W720 VMR corresponds to material number 1.6358 (X2NiCoMoTi18-9-5) and has proven to be ideally suited for many tool steel applications in cold and hot work (e.g., for extrusion stems) up to 450 °C.

Ultra-high-strength maraging steel. In contrast to heat treatable steels its outstanding tensile properties are not due to a hardened structure with relatively high carbon content, but to precipitation of intermetallic phases from a ductile nickel bearing matrix containing almost no carbon.

This results in the following advantages: High tensile strength and excellent yield point ratio, satisfactory toughness (reduction of area, elongation, impact strength, fracture toughness) even at low temperatures, superior notched tensile strength and heat checking resistance, practically no size change in heat treatment, no decarburization, no cracking, full hardening even in sizes above average. Convenient machinability in the solution annealed condition (machining is also possible in the precipitation-hardened condition). Good cold forming properties owing to reduced susceptibility to work hardening, eminent weldability, simple heat treatment at low temperatures.

| SEL | UNS |

|---|---|

| 1.6358 | K93120 |

| C | Si | Mn | Mo | Ni | Co | Ti | Al | |

|---|---|---|---|---|---|---|---|---|

| ≤ 0.030 | ≤ 0.10 | ≤ 0.10 | 5.00 | 18.50 | 9.00 | 0.70 | 0.10 |

Information on Long Products ) Presented data refer exclusivly to long products. Please observe the detailed explanations at the end of the data sheet (pdf).